Optimum cost efficiency is the key to success for a transportation company. With its lower life cycle costs, higher load capacity and fuel consumption that is up to eight percent lower, the contribution made by the new MAN truck generation can only be described as the “lion’s share”.

“Lower total vehicle costs are of paramount importance to our customers. With our new MAN truck generation, we are offering them outstanding efficiency and economy.”

Göran Nyberg, executive board member for sales and marketing, MAN Truck & Bus SE.

In the transportation industry, cost is the decisive factor when it comes to profitability and commercial success. With expenses such as wages, taxes and toll charges constantly on the rise, the market is characterised by tough competition. For transportation companies, this is a challenging basis from which to operate.

“It is our job to help customers overcome this challenge in the best possible way. For this reason, the company also placed particular emphasis on improving efficiency during the development process for the new MAN truck generation,” explains Göran Nyberg, executive board member for sales and marketing, MAN Truck & Bus SE, “because fuel consumption amounts to around 30 percent of total vehicle costs.” A typical 4×2 long-haul semitrailer tractor with D26 engine from the new MAN truck generation consumes a total of up to eight percent less diesel than a comparable semitrailer tractor from the Euro 6c generation thanks to its state-of-the-art Euro 6d engines, optimised drive axle, improved aerodynamics and GPS-assisted cruise control. So that drivers can make optimal use of the technical innovations, using digital applications, MAN also offers targeted and practical training options to support them in driving in an even more efficient manner.

The new MAN truck generation also boasts an additional savings potential with regard to life cycle costs on account of the technical improvements to products, amended repair and maintenance contracts for extended service periods and new, flexible and adaptable digital services.

GREAT EFFICIENCY & ECONOMY – FUEL CONSUMPTION

The MAN engine family – a powerful and efficient basis

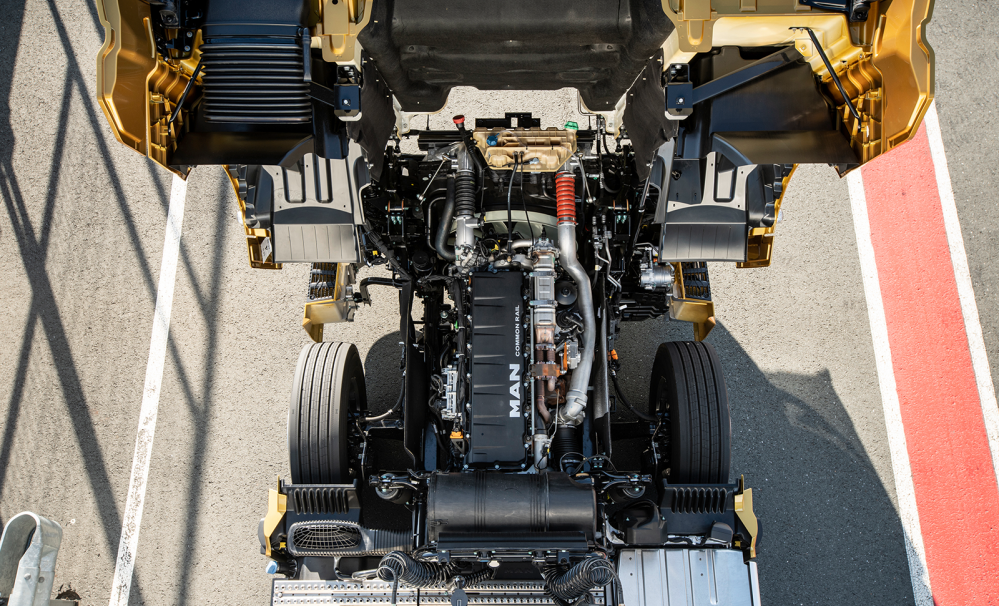

Working in perfect harmony, the components of the drive train for the new MAN truck generation improve fuel efficiency. The clean yet powerful Euro 6d engine family launched by MAN in spring 2019 provides the basis for this. Depending on the engine displacement and engine series in question, a number of different technologies for reducing nitrogen oxide and soot particle emissions are used to ensure reliable adherence to what is currently the leading emissions standard – the Euro-6d standard.

In the course of this modernisation process, MAN completely re-engineered its much-loved bestseller in the long-haul and traction segment, the MAN D26 engine. By making numerous minor improvements, it has since been possible to achieve a higher level of performance, shed around 70 kilograms of weight and significantly reduce fuel consumption. In combination with other measures, the D26 engine makes a significant contribution to the eight percent fuel saving which makes the new MAN truck generation so outstandingly efficient and economic. The 12.4 litre, six-cylinder model is available in 430 hp, 470 hp and 510 hp output variants. The torque comes in at 2,200, 2,400 and 2,600 Nm and is available from as low as 930 rpm right up to 1,350 rpm. Amongst other aspects, the optimised combustion chamber geometry with its enhanced compression characteristics and the reduced exhaust gas recirculation rate make it possible to achieve this high level of performance with a low level of fuel consumption. This results in a more effective fuel combustion process with greater peak temperatures and, all in all, a greater degree of efficiency. In addition, the overall efficiency of the engine is improved by the new, leak-free injection system with its high nozzle flow rate, new injectors with more precise injection characteristics, comprehensive measures to reduce friction within the engine, and also the reduction of gas exchange loss.

The single-stage turbo charger of the D26 is the ideal combination of efficiency and robustness. The exhaust gas recirculation module of the MAN D26 has been designed specifically with the interplay of single-stage turbocharging and reduced exhaust gas recirculation rate in mind. An electrical waste gate takes on the role of regulating the charging pressure, which makes it possible to raise the ignition pressure to 220 bar and reduces the fuel consumption further still. By integrating direct charge-air cooling, the components of the low-temperature cooling system can be removed, thus making the engine lighter and therefore more efficient. Improvements in thermal management also ensure that the thermal conditions for operation of the engine and exhaust gas aftertreatment are constant. The core element is the electrically regulated exhaust throttle valve with position feedback, which modifies the exhaust gas pressure and exhaust gas temperature quickly and precisely. Together with the regulated coolant pump, the fan speed sensor and the optimised oil cooler complete with thermostat, it ensures that the thermal conditions are constant. What’s more, the D26 benefits from the wide range of improvements that have been rolled out in all engines in the new generation. If required, for example, air compressors with a saving system can reduce fuel consumption further still. The two-stage fuel filter system and the airless Adblue injection function of the exhaust gas aftertreatment system make a further contribution.

The completely re-developed D15 engine with its nine litres of displacement and a performance range of 330 hp, 360 hp and 400 hp is particularly powerful and also very light and robust due to its highly compact and simplistic design. It generates maximum torque even at low speeds of between 1,600 and 1,800 Newton metres and is the ideal drive for weight-dependent construction applications, moderate to heavy-duty distribution transport, but also for straightforward long-haul transport operations. New construction methods and materials have also made it around 230 kilograms lighter than the D20 engine, which it has replaced since the introduction of the Euro 6d engine family.

The exhaust gas aftertreatment system on the D15 consists of refined SCR technology (selective catalytic reduction) and the self-regenerating filter system MAN CRT (continuously regenerating trap). This reduces environmentally harmful NOX emissions (nitrogen oxide) to levels approaching zero. At the same time, the D15 engine burns fuel in a particularly efficient manner, making it the ideal drive system for the mid-range performance segment of the new MAN truck generation.

Our top model in the Euro 6d engine range, the MAN D38 with 540 to 640 hp, is available for operations with higher performance requirements, such as heavy-duty transportation. The MAN D08 engine, which only came onto the market in 2018, is incorporated into the new, lightweight MAN TGL and TGM. It is available in 4-cylinder and 6-cylinder versions. This highly robust engine for the entry level performance range of 160 hp to 320 hp stands out due to its high level of efficiency and versatility, and low weight.

The D26 and D38 engines are now available with a fuel-efficient engine oil filling ex works. The properties of the new engine oil 5W-20 (MAN standard 3977) also contribute to fuel savings. Its special additives also clean the technically complex key components of the engine, prevent oil sludge build-up and, by reducing friction, prevent premature wear.

New drive axle – getting all of that power on the road

The new MAN drive axle HY-1344 also has a fuel-efficient impact on long-haul operations with a permissible gross train weight of 44 tonnes. The hypoid axle features an efficiency-optimised final drive and, in addition to the ratios available to date, also has a particularly long axle drive ratio of i = 2.31. What’s more, the axle assembly is weight and friction-optimised.

MAN EfficientCruise – Assistance system with comprehensive functions

In the new MAN truck generation, the perfectly coordinated components of the drive train are complemented by the new MAN EfficientCruise system. The GPS-based assistance system, available for the MAN TGX and TGS series, is an enhancement of the FGR cruise control and ACC adaptive cruise control systems. It determines the current position and driving direction of the truck on a continuous basis and links this information to saved road map data and the route planned on the navigation system. This enables the system to establish the topography of the road and to calculate the optimum speed and gear switching strategy for a manner of driving that is particularly fuel-efficient.

The MAN EfficientCruise system also features other functions such as “dynamic gliding” which sees the vehicle switch automatically between acceleration and rolling on flat terrain. The system causes the truck to accelerate to approx. three kilometres per hour above the desired speed and then switches the gearbox to the neutral position. The truck then rolls without the frictional resistance of the drive train to a maximum of three kilometres per hour below the desired speed set by the driver. This is followed by another acceleration phase. This manner of driving makes extensive use of the fuel-efficient operating ranges of the engine rather than the comparatively unfavourable lower partial load ranges.

When the function “variable highest speed” is in use, cruise control is not active. The driver regulates this manually with the accelerator pedal. That being said, MAN EfficientCruise continues to calculate the most appropriate driving strategy with the greatest fuel saving in the background and displays messages and small symbols on the screen of the instrumentation to provide the driver with recommendations on how to drive more economically. For example, “foot off the accelerator” at the crest of a hill to make use of the momentum. If the driver follows the instruction and takes their foot off the accelerator, then the system will allow the speed to drop by up to seven kilometres per hour when the vehicle is going over the crest of the hill. If the driver does not follow the instruction, the system will still lower the speed automatically but only by a maximum of three kilometres per hour.

If ACC is active, the speed of the vehicle in front is also factored into the calculations. For example, at the crest of a hill, the set distance to the car in front is automatically increased so that the vehicle can travel for a longer period of time on the downhill stretch without brake intervention, and the use of MAN EfficientCruise does not have to be interrupted.

Moreover, if the “Include infrastructure” function is active, then detailed map data including traffic infrastructure features such as curves, roundabouts, exits and speed limits are included in the energy-efficient driving manner calculation. Depending on the driving situation, the system also reduces the engine output when cruise control is active in order to, for example, decelerate in the most fuel-efficient manner when approaching a roundabout.

If a driver cannot or does not wish to use the automated functionality of the new MAN EfficientCruise system in certain driving situations, they still have the opportunity to improve the economic efficiency of their driving. For this purpose, the system displays efficiency-related recommendations for action on the instrumentation.

Aerodynamics – new design improves consumption values

Alongside the economic efficiency of the drive train, aerodynamics also have an important role to play in lowering fuel consumption. The more efficiently the air stream moves around the truck, the less fuel the truck requires.

The driver’s cabs have been completely redesigned in comparison to the previous series in order to keep the air resistance as low as possible. For example, narrower exterior mirror casings provide for a reduced frontal surface, and the wind guidance elements on the front panel of the new MAN truck generation improve the air conduction to the radiator and engine compartment. By extending these wind guidance elements around the doors, it is possible to calm the lateral flow of air while reducing the degree of contamination in this area. The “air curtain” on the corners of the bumpers optimises the flow of air around and through the entrance area. Depending on the type of driver’s cab, new roof spoilers and side flaps are the final parts to direct the airflow from the truck towards the semitrailer.

The extent to which enhanced aerodynamics improves fuel efficiency is determined predominantly by driving speed. The higher the average speed, the greater the proportion of the overall driving resistance that is attributable to air resistance. As such, it is predominantly the vehicles of the new MAN truck generation that are used for overland and long-haul transportation that benefit from improved aerodynamics.

MAN Digital Services – promoting an efficient driving style

The new MAN truck generation offers vast technical potential for fuel economy. However, the driver continues to be a decisive factor in the ultimate level of consumption. For this reason, MAN provides drivers with digital services that help them to drive in the most fuel-efficient manner possible.

In addition, the MAN Perform application evaluates all of the relevant vehicle data such as the average fuel consumption, cruising range, use of cruise control or the service brake. These data analyses provide a meaningful basis for driver evaluations, which can then be drawn on to select suitable courses and training that will help drivers to improve and refine their fuel-efficient manner of driving.

One of these measures is the MAN Connected CoDriver Training course, an ideal training opportunity for truck drivers that takes place right behind the steering wheel. An MAN ProfiDrive trainer calls the driver in their driver’s cab at an agreed time and provides them with clear and specific tips over the hands-free system. Throughout the entire training period, the MAN ProfiDrive trainer uses the data from MAN Perform to analyse the driving performance of the driver and establish a basis for live coaching. The trainer then provides the driver with valuable tips in real time on how to drive the vehicle in a more fuel-efficient manner. These driver coaching sessions are typically held on a weekly basis over the course of two to three months, thus guaranteeing an ideal and sustainable learning outcome. Coaching is available in English, German, Dutch, Danish, Italian, Spanish and Polish.

GREAT EFFICIENCY & ECONOMY – LIFE CYCLE COST

Reduced wear – state-of-the-art technology for a longer service life

So as to ensure that the new MAN truck generation would remain profitable for transportation companies throughout its entire service life, operating costs were made a key topic of focus during the development process. Particularly long-lasting wearing parts have a vital role to play in this. For example, the new, LED front lighting system not only looks modern, it also brings with it very specific economic advantages as it is characterised by a very low level of energy consumption and a service life that is significantly longer: Up to 50, 000 operating hours. This equates to around 15 years or 1.5 million kilometres and results in lower maintenance costs. If a light does need to be replaced, then the re-engineered driver’s cab entrance provides straightforward access to the lights, simplifying the maintenance procedure considerably.

On a more basic level, the new MAN truck generation features a wealth of newly developed or improved components that wear out less quickly, weigh less and contribute to significantly reduced maintenance costs.

Maintenance intervals – intelligently extended cycles

To minimise maintenance costs and the time spent at the workshop, the maintenance intervals have been cleverly adapted to account for the improved consumption and wearing behaviour of the new engine generation. Depending on the vehicle type and deployment profile, it is now possible, for example, to have oil-change intervals of up to 140,000 kilometres or an oil change time interval of up to 18 months for the D38 and D26 engines. The maximum cleaning interval for the diesel particulate filter can now be 800,000 kilometres for the D38 or even up to 900,000 kilometres for the D26.

MAN service contracts – perfectly tailored maintenance packages

If these maintenance jobs and other maintenance work are due to take place or if an unscheduled repair ever needs to be carried out, then the harmonious portfolio of MAN service contracts will ensure that you are not faced with an unexpected financial burden. The basis of all of our service offerings is the proactive, digital maintenance management scheme MAN ServiceCare, which evaluates all of the relevant vehicle data pertaining to the truck. MAN Service Care comes free with all vehicles in the new MAN truck generation.

ComfortOil is MAN’s cost-efficient entry level product that safeguards vehicle quality by providing an optimum service and perfectly tailored oils for the engine, axle and gearbox, not to mention valve clearance adjustment. There is also the option of extending the guarantee to cover the drive train or the entire vehicle. The Comfort package combines all of the services and inspection work that are listed in the vehicle maintenance plan into an all-inclusive price. The ComfortPlus package includes an extension of the driveline guarantee in addition to the services covered by the Comfort service contract. If desired, the guarantee can be extended to include an enhancement package or, alternatively, extended to cover the entire vehicle. In addition to the services listed in the Comfort service contract, the ComfortSuper package also covers all wear-and-tear repairs and any other repairs to any part of the vehicle. This contract provides comprehensive cover for all costly components of the vehicle. The range of service contracts is rounded off by the ComfortManaged contract, which provides comprehensive and simplified fleet management with a flexible scope of service and conditions that are determined by the individual customer – for all of the brands and types of commercial vehicles that make up the entire fleet. This is also intended for trailers.

GREAT EFFICIENCY & ECONOMY – PAYLOAD

Significant payload advantage – lighter components pay off

Each and every model in the new MAN truck generation stands out due to its outstanding fuel economy and minimised operating costs. Alas, there is one aspect in which the new MAN truck generation is not frugal at all, and that is its payload.

To further increase economic efficiency in particularly payload-sensitive areas of application, it is vital to design the components of the vehicle to be as light as possible. With this new MAN truck generation, our developers have succeeded in reducing the weight to such an extent that we can continue to offer an optimum payload balance despite the heightened ECE-R 29-3 crash safety requirements, which will become binding from 2021, and the reinforced shell structure of the driver’s cab, which is now required as a result of said requirements. Depending on the vehicle model and configuration, it is possible to make a payload gain of up to almost 300 kilograms.

MAN Turbo EVBec – top brake output, even without a secondary retarder

For example, the serial production model of the payload-optimised TGS-TS semitrailer tractor with its D15 engine and FN driver’s cab has a payload capacity that is more than half a tonne greater than a standard long-haul tractor. The TGS-TS is particularly suitable for transporting tanks and silos. This is aided in no small way by the optional, top-of-the-range engine retarder, MAN Turbo EVBec, which, depending on the output variant of the engine, can deliver an engine brake output of up to 350 kilowatts on a continuous basis. The brake output remains consistent even on long downhill stretches which also represents a significant increase in safety, particularly on steep downhill gradients. Depending on use, there is no requirement for a secondary retarder. Consequently, a further weight saving of 60 to 90 kilograms can be made, subject to the gearbox design.

Compact driver’s cabs – low base weight wins customers over

On account of their narrow width, the compact driver’s cab variants FM and FN are particularly well-suited to payload-intensive, special-purpose applications in the domestic long-haul transport and heavy-duty distribution transport sectors. Due to the aerodynamic, narrow front of the vehicle, these driver’s cab variants use less fuel than wider long-haul driver’s cabs. For example, the payload-optimised semitrailer tractor TGS-TS with its FN driver’s cab and D15 engine has a ready-to-drive unladen weight of well under 6,500 kilograms as standard. In comparison to a D26 standard semitrailer tractor, this relatively low weight allows for a higher payload. By opting to have additional equipment options factory-fitted and modifications carried out by MAN Individual, the unladen weight can be reduced further still by up to 205 kilograms.