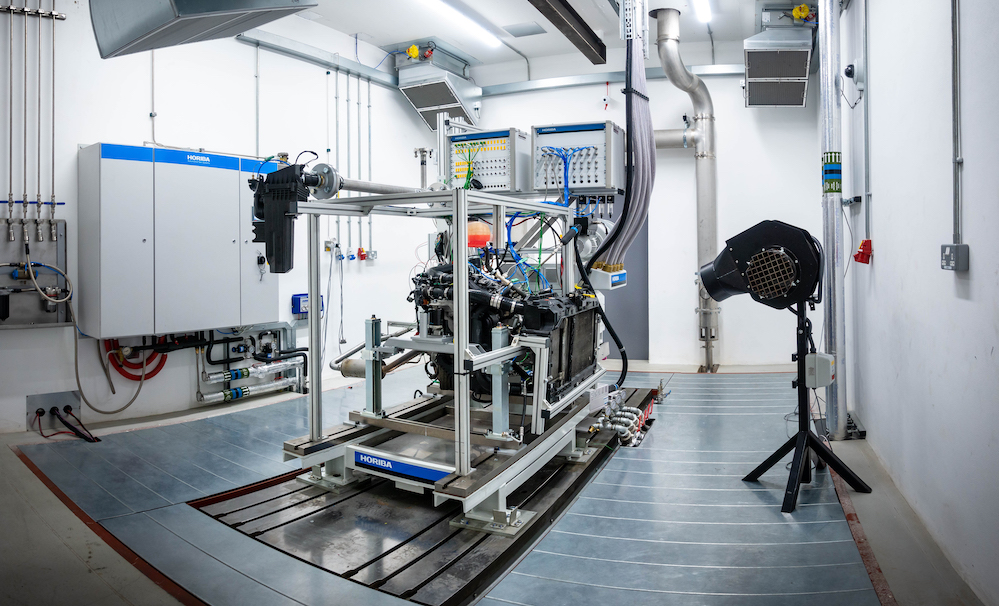

As part of its commitment to helping vehicle manufacturers produce cleaner vehicles, HORIBA MIRA has opened a new Propulsion Test and Development Centre at its UK headquarters in Nuneaton.

In an exciting leap forward for the business, the Propulsion Test and Development Centre is a state-of-the-art testing facility for engine development, providing emissions, performance and validation testing with the latest simulation hardware, which effectively replicates environmental conditions such as temperature, pressure and humidity.

The centre has been specifically developed in response to the need for OEMs to meet ever-stringent emissions standards since the introduction of the Real Driving Emissions (RDE) test in 2017.

Where traditionally customers have relied on on-road testing to develop RDE compliant propulsion systems, the Propulsion Test and Development Centre capabilities will essentially enable RDE testing with “Engine in the Loop” (EiL) to be carried out in a simulated environment across all the RDE boundary conditions without the need for a vehicle. Designed to complement HORIBA MIRA’s Advanced Emissions Test Centre RDE capability, it will allow OEMs to engineer a vehicle for emissions compliance much earlier in the development cycle, resulting in significiant time and cost-savings.

The new testing lab represents a significant investment for HORIBA MIRA, a world-leader in advanced automotive engineering, research, development and testing, with the company spending more than £4m on the latest technology. This includes the addition of the unique HORIBA MEDAS system which can accurately replicate real-word altitude conditions for vehicle emissions testing, into both the Propulsion Test and Development Centre and the Advanced Emissions Test Centre.

Declan Allen, Managing Director at HORIBA MIRA, said: “Recognising the rising challenges facing our customers when it comes to engine development and meeting stringent emissions standards, we’ve invested heavily in creating our new state-of-the-art Propulsion Test and Development Centre.

“As one of very few facilities of its kind around the world, the result is the ultimate engine development lab, where businesses can have all of their performance, testing and validation needs taken care of under one roof – making the process of creating a vehicle for emissions compliance effective and efficient. We look forward to welcoming all our customers, new and existing, to take advantage of this fantastic facility.”

As a secure, confidential and independent test facility, the Propulsion Test and Development Centre includes steady state to high dynamic, low inertia dyno engine testing with emissions measurements, together with experienced engineers and technicians on hand to meet customer specific requirements.