Temperature-controlled transport systems are vital for preserving perishable goods in the haulage industry. Regular maintenance is crucial to ensure these systems function efficiently and avoid costly breakdowns. Implementing effective maintenance practices is essential for optimising operations.

Transporting perishable goods requires precise temperature management, making temperature-controlled systems indispensable in the haulage sector. These systems allow you to maintain specific temperature ranges, ensuring products reach their destination in optimal condition. Without regular maintenance, these systems are prone to failures that can lead to significant financial losses and reputational damage. Understanding the components and their maintenance needs is key to effectively managing your fleet’s temperature-controlled transport systems. Addressing potential issues before they escalate into major problems is vital to maintaining system reliability. For more detailed information on how to manage these systems, you can explore cold room parts and their specific maintenance requirements.

Components of Temperature-Controlled Transport Systems

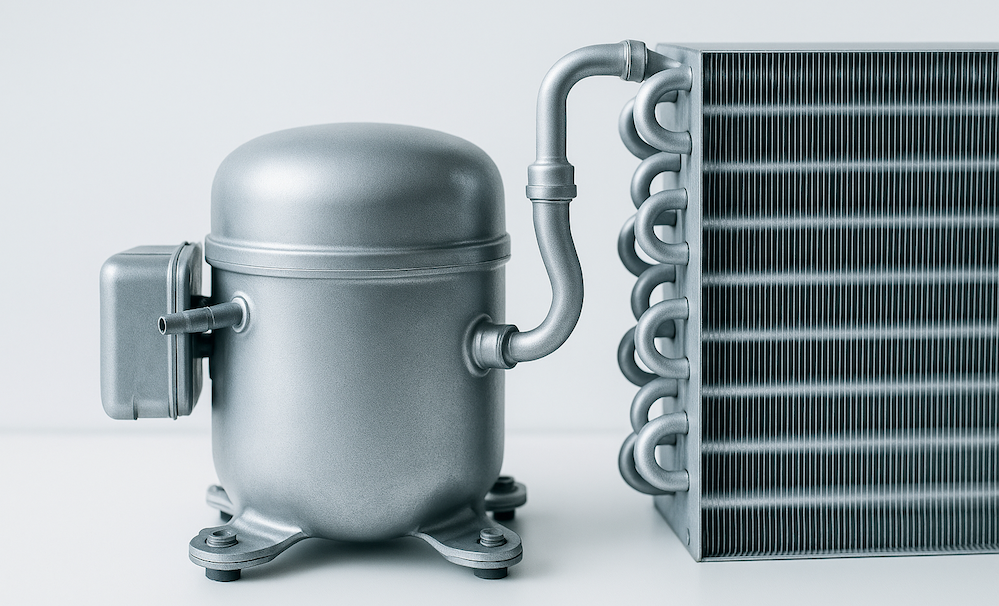

Temperature-controlled transport systems consist of various components, each playing a vital role in maintaining product integrity. Refrigeration units form the backbone of these systems, providing the necessary cooling to keep goods within the desired temperature range. Regular checks on these units, including compressors and evaporators, help ensure efficient operation and prevent unexpected failures.

Insulated doors are also crucial in maintaining consistent temperatures within transport vehicles. They prevent external heat exchange, preserving the internal climate necessary for sensitive cargo. Ensuring that door seals are intact and insulation materials are undamaged is an essential maintenance practice. Neglecting these elements can lead to energy loss and reduced system efficiency, ultimately affecting cargo safety and quality.

Routine Maintenance Practices

A proactive approach to maintenance involves conducting regular inspections and servicing of all system components. These routine checks should focus on identifying wear and tear, as well as any signs of malfunction within refrigeration units. Regularly monitoring temperature settings and recalibrating as necessary can help maintain optimal performance and extend equipment lifespan.

Operators should also be vigilant for potential issues such as unusual noises or leaks in refrigeration units, as these may signal underlying problems. By addressing these warning signs early, you can prevent more severe disruptions that could lead to complete system failure. Additionally, maintaining a detailed log of service history enables operators to track performance trends and plan future maintenance activities more effectively.

Benefits of Regular Maintenance

Consistent maintenance offers numerous benefits beyond preventing unexpected breakdowns. It ensures compliance with industry standards that mandate specific operational conditions for transporting perishable goods. Meeting these standards not only safeguards your business from legal repercussions but also enhances customer trust by guaranteeing product quality upon delivery.

Moreover, efficient maintenance contributes to overall operational efficiency by minimising downtime caused by equipment failures. This reliability translates into cost savings on repairs and reduces the risk of cargo spoilage due to temperature fluctuations. For many operators, this highlights the importance of integrating comprehensive maintenance routines into their operational strategies to protect both assets and reputation.

Proactive Strategies for System Longevity

Incorporating a proactive maintenance strategy is crucial for haulage operators aiming to maximise the lifespan of their temperature-controlled transport systems. By prioritising regular upkeep, you can ensure your equipment remains in excellent working condition year-round. This commitment to maintenance fosters operational stability and allows you to focus on delivering exceptional service to your clients.

The adoption of advanced monitoring technologies provides real-time insights into system performance, enabling quicker responses to potential issues. Investing in such technologies underscores your dedication to maintaining high operational standards while reducing long-term costs associated with emergency repairs or replacements. Ultimately, embracing proactive maintenance practices sets the foundation for enduring success in the haulage industry. To further enhance your operational strategies, consider exploring temperature-controlled transport systems that offer innovative solutions for maintaining optimal conditions.