Subscan UDS, the nationwide utility, drainage, and survey company, has implemented a mobile operations system from Leeds technology company BigChange. The system, which provides a paperless means of planning, managing, scheduling, and tracking mobile operations, has provided Subscan with a 30 percent saving in time and a million-pound growth boost to its business.

Subscan provides a wide range of services aimed at the detection and avoidance of underground utilities, as well as drainage maintenance and repairs. A team of specialist technicians operate across the UK undertaking everything from topographical surveys to underground utility tracing, drainage, CCTV surveying and the lining of drains.

“We go and map areas identifying all structures and utilities above and below ground and then sort out any issues – we deal with all major infrastructure. We offer a full service package from initial survey to remedial work,” says Kirk Mason, Operations Director, Subscan.

Subscan has been a success story since formation only 7 years ago with steady year on year growth. However the previous IT system was proving to be a barrier to growth and with the move to BigChange the company has been able to expand and turnover is expected to increase from £6 million last year to £9 million in 2020.

“Our previous system only offered partial automation and we wasted a lot of time double touching to keep different systems up to date,” says Mason. “What we needed was a seamless flow of data from start to finish with an audit trail of activity. In the end there wasn’t anything that matched BigChange for functionality; it gives us that seamless connectivity and it has replaced 5 separate systems – saving us time and money.”

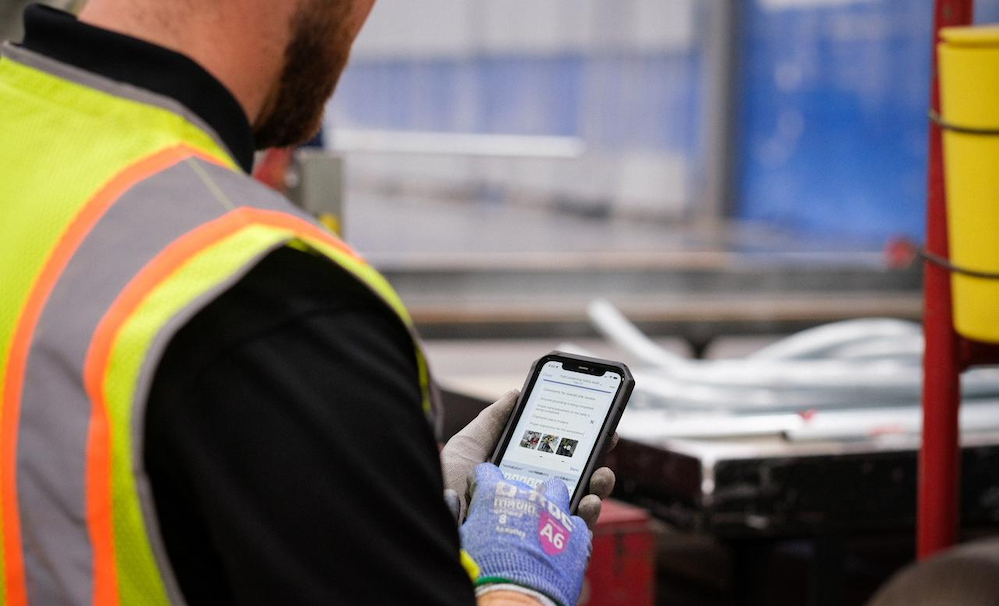

Subscan has equipped 50 of its field operatives with rugged tablets running JobWatch, the BigChange app for paperless working. Jobs are scheduled and sent to the assigned operative who can proceed straight to the job and with trackers on the fleet, the office has real time visibility of their locations.

“With BigChange we are now very much paperless; it has been a complete digital transformation and the savings are significant. For time alone we are achieving savings of 30 percent and that’s before we even begin to look at the improved job scheduling and productivity,” explains Mason.

“One thing is very clear, since implementing BigChange we simply don’t get KPI failures as we are right on top of the workload and that’s meant we meet out SLA commitments and deliver a level of service we simply could not provide before,” he adds.

BigChange vehicle tracking is not only useful for providing visibility to operations and customer services back in the office but it is also helping improve the quality of driving. Driver performance based on factors such as speed, braking, cornering and idling is graded automatically and those operatives with high ratings are rewarded with extra holiday vouchers.

Subscan has made a multi-million pound investment in the most advanced fleet of specialist vehicles in the UK. The 60 vehicle fleet includes JHL 312 and 414 recyclers and Mercedes Atego 204 Cityflex units. The JHL SuperRECycler 414, built on a Scania chassis, is the markets most powerful and productive recycling unit and both JHL models have fully automatic water filtration systems that continuously separate water from sludge to subsequently use the cleaned water to clean the sewer. Subscan has also invested in a JCB Fastrac 7230 tractor for rugged terrain operations.